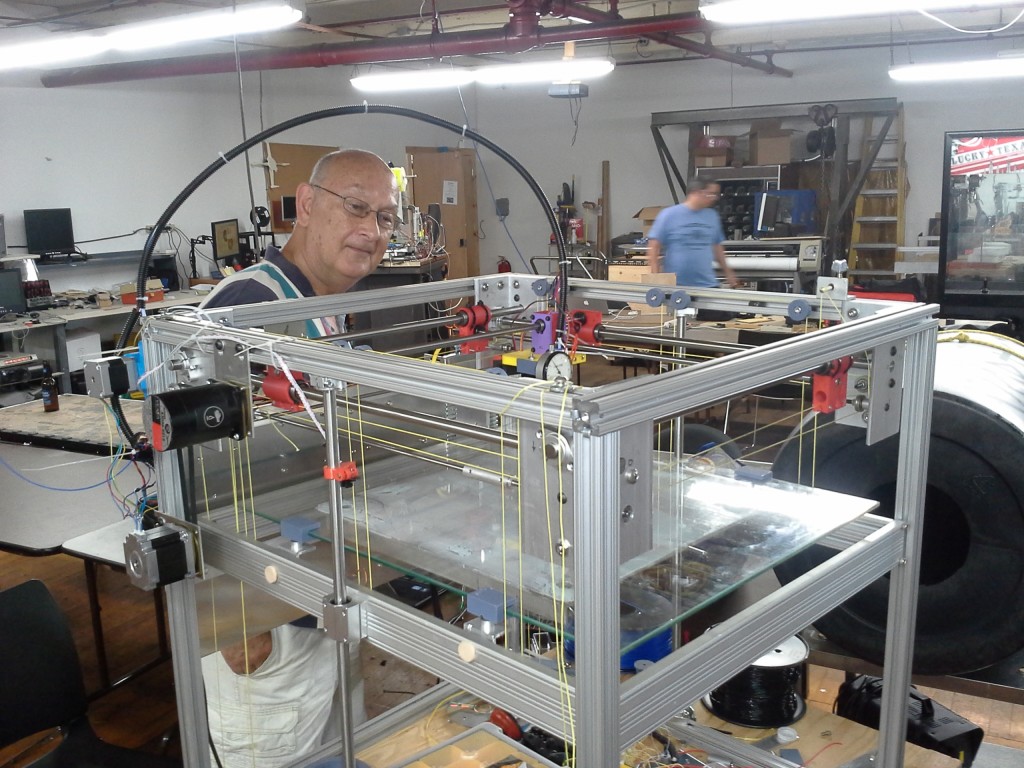

Harvey has been working on this unreasonably huge 3D Printer for longer than most of the other members have been alive. Well, today marks a momentous occasion, it now moves in all 3 axes!

Harvey has been working on this unreasonably huge 3D Printer for longer than most of the other members have been alive. Well, today marks a momentous occasion, it now moves in all 3 axes!

The printer design is 100% Harvey. It’s all scratch built and went through many on-the-fly revisions during the assembly process. The frame is a 2 foot cube and the print area will be 15 inches cubed. He’ll have to rent a pickup truck to move it!

The Z-axis isn’t leadscrew or belt driven like found on most printers. Here, there’s an elaborate system of kevlar fishing line and pulleys. Today it worked perfectly, raising and lowering the print surface evenly. Now it’s time to set up the firmware and limit switches!